Terminal at Hamriyah Free Zone, Sharjah, UAE

Construction of the terminal at the Hamriyah Free Zone, Sharjah, UAE is on track and well within its projected time line of September 2016. The petrochemical and petroleum terminal we are proud to say will be the first facility of its kind in the region to offer distillation, hydrogenation and fractionation process. The group is very excited about the vast new business opportunities and possibilities with its completion and are working hard to ensure it keeps original timelines.

HAZEL INTERNATIONAL FZE (HIF) & ITS TANK TERMINAL

ADVANTAGES

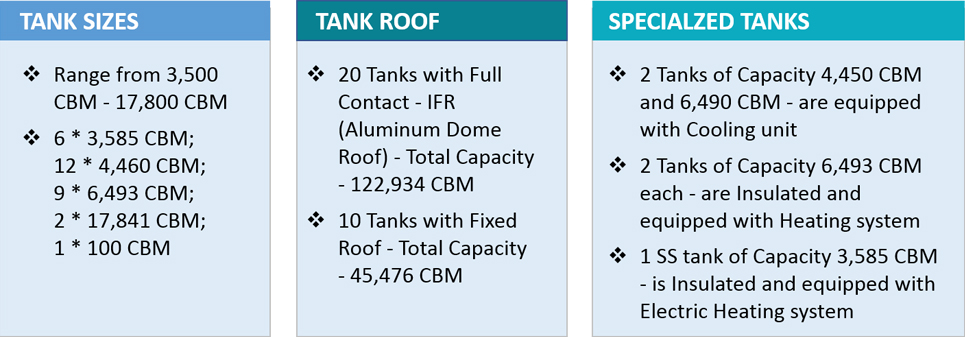

- 30 storage tanks – Total Capacity – 170,000 CBM. Tank size ranging from 3,500 BM to 17,800 CBM

- Can handle full spectrum of petroleum products: Classified: Class A/B/C and Non-Classified along with Petrochemicals

- Only terminal in the Middle East that can handle multiple categories of specialty products under one roof. E.g. Products that need Cooling, Products that need Heating, Products that need Stainless Steel Tank, etc.

- Address the supply gap for petrochemical storage facilities in UAE; most of the terminals operate in oil & gas space with limited capabilities to store all grades of chemicals

- 20 Internal Floating Roof Tanks: which means it can handle volatile Products like Gasoline, Aviation Kerosene, Crude oil and other light oil. Advantage: No evaporation space above the liquid, therefore, reducing the evaporation loss by 90%~95%.

- Shortest Main Jetty Lines – approx. 500 Meters – Quick Vessel Loading / Unloading Operations compared to other terminals (avg. jetty line of 1.5 km) and lesser Slops. 4 Jetty Lines – 2 * 16” Line for Clean Products, 1 * 10” Line – Fully Heat traced for Bitumen and Dirty Products, 1 * 10” Line – Stainless Steel Line

- Full integrated terminal providing complete end to end solution for liquid cargo handling

- Tanks with Cooling Unit – For Products that needs to be maintained below ambient temperature – E.g. Monomers like Styrene Monomer

- Tanks with Insulation and Heating unit – Bitumen / Fuel Oil

- Stainless Steel Tank with Heating System – for special Products like Phenol / Acetic Acid

- All tanks have individual lines and pumps: ensures positive segregation.

- 7 Specialized Truck Loading Bays – Each Bay can load a minimum of 100 Trucks per day and installed with Mass Flow meters

- Drumming Station for Bitumen & Petrochemicals with Palletization & Container handling – Adding to 67,500 Drums per Month and the capacity can be enhanced as well.

- Advanced Blending system for homogenous mixing

- In house Laboratory

- Only Distillation Unit in Emirates with direct access to Jetty and within the terminal compound. It also connects to 9 Stainless Steel Storage tanks for smoother operations

- Nitrogen Plant: Bulk liquid nitrogen for Blanketing, Inerting & Pigging

- Multipurpose Admin Building of 5 floors with dedicated space for Lab / Surveyor room / Sample room and capable of seating over 100 employees

- Automated Terminal – integrated with Distributed Control System by HoneyWell

- 2 Weigh Bridge Facilities for Quicker and smoother Operations

- Elaborate Fire Fighting System specially designed for Class A terminals

- Inter Tank and Inter Terminal Cargo Transfer provision

- The terminal was constructed by one of the leading Industrial Developers – TATA Project

- The terminal durability and sustainability is upto 50 years – main reason being the quality of work and the equipment used

- Robust Terminal design which allows the Operation team to handle multiple products

TERMINAL HIGHLIGHTS

- 30 Storage Tanks – Total Capacity: about 170,000 CBM

- Distillation Unit – Processing Capacity – upto 500 MT / Day

- Class A/B/C Products, Petrochemicals and Non-Classified Products like Bitumen and Base Oil

- All tanks made in accordance with international design standards i.e. API 650 & API 2000

- In built safety features, tanks have internal floating roofs to minimize vapor losses